The First test which one should be performed before construction is the safe bearing capacity of the soil. It’s a preliminary test that should be conducted before the construction of any structure. It is recommended that the safe bearing capacity of soil should be tested at all the points of footings.

What is a Safe Bearing Capacity of Soil?

A safe bearing capacity of soil field test is done to check the capacity of the soil to withstand loads. Let us consider an example of a small plastic chair, This small plastic chair is made for kids and It can bear a capacity of 10 Kgs. Suppose, if an adult sat on it, then Chair will be broken. The same case is applied to the soil, If more load is applied on soil than its resistance, then soil starts displacing or breaking which leads to settlements. In order to keep the structure safe, the Safe bearing capacity of a soil is calculated on the field at different points and the selection of footing is done accordingly.

The maximum load per unit area which the soil can bear without any displacement or settlements is designated as the “Safe bearing capacity of the soil.”

Safe Bearing Capacity of Soil formula:

Ultimate Bearing Capacity of Soil:

The point at which soil starts displacing is called the Ultimate bearing capacity of the soil.

For Example: Take a rubber band and stretch it oppositely, Rubberband has an elastic property which it can regain back to the original position. If u start stretching it more, it may break at a certain point, that point is known as the Ultimate point of Rubberband where it loses its elasticity and it won’t come back to its original position.

The same can be applied to the soil, Soil has an ultimate bearing capacity where it can bear the load up to a certain point. After that point, Soil starts displacing (Settlements). That point is called as Ultimate bearing capacity of the soil.

The ultimate bearing capacity of soil varies with the type of soil and the atmospheric conditions.

The factor of Safety depends upon the type of construction and it usually ranges between 2 and 3. For High rise constructions, we go with F.O.S 3.

Safe Bearing Capacity of Soil Testing Procedure:

Well, so many theories explained how to find the safe bearing capacity of the soil. Among them, the Drop weight method is the easiest and reliable test.

Drop weight method:

This method is the field test for the Safe bearing capacity of the soil.

- Firstly Excavate a pit of required depth. (preferably equal to the depth of foundation)

- Take a square cube of known weight and dimensions.

- Now drop the square-cube on the pit with a known height.

- Measure the impression made on the pit by square cube using the scale.

(For accurate results, Drop the cube several times on the same pit and calculate the average depth of Impressions “d”.)

Example:

Weight of Cube = 0.6Kg, Height of fall = 120cm

Depth of impression = 0.8cm;

Cross Section Area (A) = 20cm2; Factor of Safety=2

Depth of impression = 0.8cm;

Cross Section Area (A) = 20cm2; Factor of Safety=2

Ultimate Bearing Capacity [UR] = [0.6 x 120]/0.8 = 90Kg

Safe Bearing Capacity of Soil = 90 / [20 x 2] = 2.25Kg/cm2

Why calculate the Safe bearing capacity of the soil before starting construction:

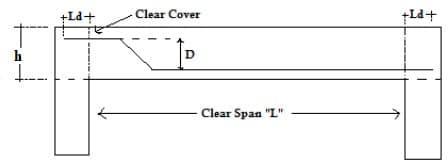

From the above figure, it is clear that the building is fallen on only one side. It is occurred by the settlements on one side of the building, due to this the building is overturned on one side but didn’t collapse.

The reason for this is The safe bearing capacity of the soil is enough at one part of the building, but not the other part. It is recommended to check the SBC of soil at all footing positions to overcome the Soil Liquefaction. And the perfect type of footings is chosen by checking the Safe bearing capacity of the soil.

Safe bearing capacity (SBC) Values for different types of soils:

These are probable values that are only used only for preliminary design. The actual safe bearing capacity of the soil is calculated by using IS mentioned Codes.

/162) Equation 7

/162) Equation 7